Water is essential for life — but in manufacturing, even a drop too much (or too little) can ruin a product. From pharmaceuticals to fuels, the moisture content of raw materials and finished goods directly affects performance, safety, shelf life, and compliance.

Moisture content impacts:

- Quality → texture, stability, and usability.

- Safety → microbial growth, corrosion, chemical reactions.

- Compliance → meeting pharmacopeia, ISO, or ASTM standards.

That’s why moisture and water content testing isn’t just a lab exercise — it’s a critical quality checkpoint.

What Is Moisture/Water Content Testing?

Moisture testing determines the exact water level in a product, whether solid, liquid, or powder. This can be expressed as a percentage, in parts per million (ppm), or in other units depending on the application.

While the concept sounds simple, the stakes are high:

- Too much water can trigger microbial growth, corrosion, unwanted chemical reactions, or product instability.

- Too little water can alter texture, reduce efficiency, or even cause a product to fail its intended purpose.

For regulated industries, wrong measurements can risk compliance audits or recalls.

Why Moisture Testing Matters — Industry by Industry

Every industry has its own reason for moisture control. For instance, a capsule in pharma must have tightly controlled water levels for potency. In food, excess moisture can cause mold and spoilage. In petroleum, even ppm levels of water can corrode engines. Cosmetics must maintain texture (no drying out or separating), while environmental testing relies on water content to guide agriculture and waste management.

The goal is always the same: control, consistency, and compliance.

- Pharmaceuticals – Guarantee drug potency and stability, ensuring compliance with pharmacopeia standards.

- Food & Beverage – Prevent spoilage, ensure safety, and meet strict labeling requirements.

- Petroleum & Lubricants – Detect contamination that can cause corrosion, reduce performance, or destabilize fuels.

- Chemicals & Polymers – Maintain product uniformity, prevent hazardous reactions, and streamline manufacturing.

- Cosmetics & Personal Care – Preserve texture, stability, and shelf life while meeting consumer expectations.

- Environmental Testing – Monitor soil, sludge, and waste moisture levels for sustainability and agricultural planning.

How It’s Done — Precision Matters

The right method depends on your product, regulations, and desired accuracy.

- Loss on Drying (LOD) → involves heating a sample until weight stabilizes. It’s quick but may measure volatiles other than water.

- Infrared methods → non-destructive and rapid, ideal for production checks, but often require calibration.

- Gravimetric methods → traditional, widely used in food testing, but can misrepresent actual water levels.

- Karl Fischer titration → globally recognized for pinpointing even trace moisture down to 1 ppm with high precision — making it the preferred method where regulations demand accuracy.

👉 While other methods have their place, Karl Fischer is the industry choice when compliance and precision matter most.

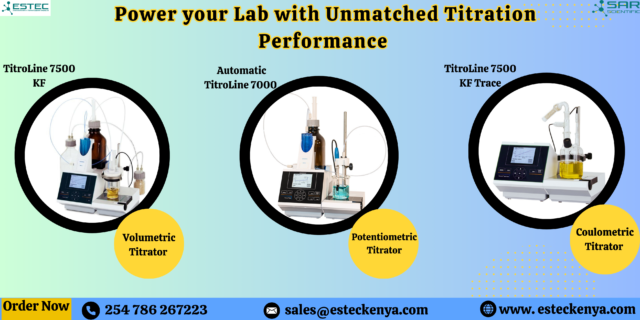

Our Solutions — SI Analytics TitroLine® Titrators

We offer KF titration solutions tailored for all industries.

- TitroLine® 7500 KF Trace → Ultra-low water detection (1 ppm to 5%). Perfect for petroleum, pharma, and specialty chemicals.

- TitroLine® 7500 KF → Flexible volumetric testing for a wide range of samples — % water or ppm.

- TitroLine® 7000 → Multipurpose titrator: water content plus non-aqueous titrations (like TAN/TBN in oils).

Our instruments are designed for both routine QC labs and specialized R&D environments. Whether you’re checking trace moisture in fuels or % moisture in powders, the TitroLine® range provides precision, compliance, and flexibility.

Choosing the Right Testing Instrument

The best choice depends on:

- Moisture range (trace ppm vs percentage)

- Sample type (solid, liquid, oil, powder, gas)

- Precision & compliance needs (pharma, ISO, ASTM, etc.)

- Automation level (manual vs integrated systems)

No two labs have the same needs. For a petroleum lab following ASTM standards, the 7500 KF Trace is ideal. A pharma lab needing % water and trace detection may choose the 7500 KF. For labs handling oils, the 7000 adds flexibility for TAN/TBN titrations alongside water determination.

Final Word

Moisture testing is not just another step — it’s a safeguard for:

- Product quality

- Regulatory compliance

- Your brand’s reputation

💡 When accuracy matters, Karl Fischer titration is the gold standard — and SI Analytics TitroLine® titrators deliver it with confidence.

👉 Get in touch today to find the right KF solution for your lab.

📞254 786 267223 🌐 www.esteckenya.com 📧 marketing@esteckenya.com sales@esteckenya.com

📌 4th Floor, West One Building, Wambugu Grove, Off Parklands Road, Nairobi, Kenya.